Most common uses of MDF

MDF has become one of the most commonly used construction materials, even as popular as plywood. Although it might not be exactly like natural wood, it is far more affordable and has many different qualities that have led to it becoming widely used. Here are some of the most common uses of MDF and how effective it is in each of these applications.

But first...

What is MDF?

MDF, short for Medium Density Fibreboard, is a wood product made by combining wood fibres with wax and a resin binding agent. Once the wood fibres and glue are mixed, they're pressed into flat panels using high temperatures and pressure. MDF is available in both sheet and panel form, and it can be cut and shaped to meet the needs of any project.

Similarly to plywood and particle board, you'll be able to find large sheets and panels of MDF at varying different thicknesses, usually starting at around 3mm and going all the way up to more than 30mm. You'll also be able to find medium-density fibreboard with different qualities, such as Flame Retardant MDF which has been specially treated to suppress fires.

MDF is one of the most affordable wood products, making it an excellent choice for DIY projects and furniture building. In addition to its cost-effectiveness, another benefit of MDF boards is that they are much easier to paint on as they have a smooth surface. Just seal the MDF material with PVA glue or an oil-based primer beforehand. It's also easier to use and more flexible than other wood- and wood-based products.

Due to its different qualities, medium-density fibreboard is used for various other purposes. Here's a list of some of its most common applications.

Making furniture

One of the most common uses for medium-density fibreboard is to make low-cost furniture. If you've ever purchased a piece of flat-pack furniture, it was likely constructed with MDF boards. This is because MDF boards are much easier to work with than solid wood and are also significantly cheaper to produce, lowering the overall cost of manufacturing. You can also easily paint the boards to make them look much nicer and achieve your desired look.

Some people mistakenly assume that MDF boards are only used for low-end furniture. However, there are many different types of MDF, some of which are stronger and moisture-resistant. This means that MDF is a versatile material for furniture making.

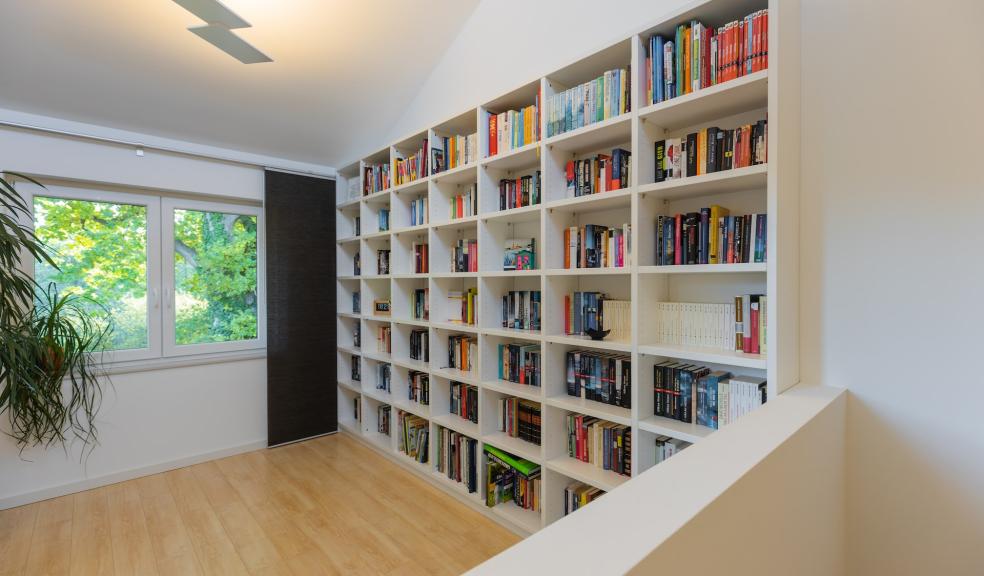

Cabinetry & shelving

MDF is also frequently used to construct interior cabinets and shelving, although how much of the cabinet is made of MDF sheets depends on the cabinet size. If it is smaller, the entire cabinet may be made of MDF sheets, whereas larger cabinets might be mainly constructed with solid wood but will have a door made of MDF boards. You'll also be able to build bathroom vanities if using moisture-resistant MDF, as this material can withstand the humidity of bathrooms.

If you're nervous that your MDF-constructed cabinet needs to be stronger for shelving purposes, don't be. Although not as strong as solid wood, MDF boards can hold glasses, plates, and other kitchen utensils perfectly. For cabinets entirely made of MDF they're typically veneered with a wood laminate on top.

Soundproofing

This might surprise many people, but MDF boards can be used to effectively soundproof a space. Medium-density fibreboard can reduce the movement of sound waves because of the lack of vibration in the sheets. Many speaker production companies will use MDF sheets in speaker casing builds as they absorb sound and don't vibrate from inside the speaker casing.

Music studios will tend to have boards of MDF built into the walls to prevent sound from travelling through the walls. Sheets of MDF have also been used outside of music-related settings, such as apartments and office buildings, to dampen the sound and minimise noise pollution.

It might not be the most foolproof soundproofing material on the market, but it's an excellent low-budget sound dampener for your home.

Vapour repulsion

Although not completely waterproof, MDF boards can be used as an effective vapour barrier. It should be noted that this is only applicable to certain types of moisture-resistant MDF manufactured with special resins. When these types of MDF boards are exposed to moisture and humidity, they can dry out without shrinking, rotting, or cracking. They become even more effective when supplemented with moisture-resistant paint and other vapour-repelling treatments.

Moisture-resistant MDF boards are most commonly used in the construction of bathrooms, kitchens, floors, and other areas with high humidity levels that would cause standard MDF sheets to swell. However, these areas should ideally be well-ventilated as water-resistant MDF can disintegrate if it stays wet for too long.

Roofing

MDF boards aren't just used for interior design; they can also be used for exterior builds. Water-resistant MDF boards can be used as a more affordable roofing material, with the panels acting as backing for shingles. This is especially useful if the roof has low slopes.

Some MDF panels are specially produced for exterior purposes and are moisture, termite, and rot-resistant. Exterior MDF also tends to be thicker and denser than regular MDF.

Fire resistance

When you think of wood-based materials, you might only immediately expect them to be fire-resistant. But there is a type of MDF that is designed to be fire retardant. Fire-resistant MDF consists of special chemicals that prevent the board from combusting as the fire cannot take hold.

Many buildings require fire retardant MDF, especially offices, kitchens, and other structures that must follow particular building and safety requirements. Fire retardant MDF is not 100% fireproof; however, it can slow down the spread and severity of fires. Essentially, it gives you more time to suppress and stop the fire.

Flooring

MDF wood can also be used for flooring. Tile manufacturers often use MDF to produce wood effect laminates and tiles, especially when these tiles are made for areas with minimal foot traffic and moisture. This is because MDF panels aren't as strong as other woods, such as plywood or solid hardwood and wouldn't hold up well in high traffic or wet areas. MDF sheets are often better used as underlayment, placed between the floor and subfloor, due to their effectiveness at insulation and soundproofing.

MDF: Your multi-purpose material

In conclusion, medium-density fibreboard is a tremendous multi-purpose material. MDF wood has proven to be a genuinely versatile construction material for flooring, soundproofing, furniture making, and roofing. The next time you're looking for materials for your next carpentry project, look at MDF panels. There's a high chance you'll find the right type of MDF for you.

If you're looking for various MDF types for your next project or build, visit Cworkshop. The London-based cut and edge specialists can help you get started by providing a wide range of MDF options and an MDF cutting service.